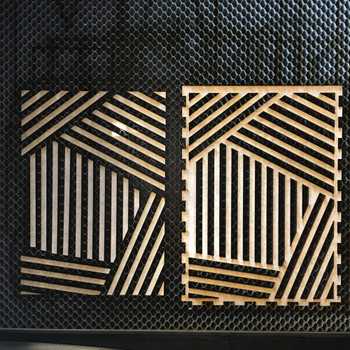

Starting to get into a few 3D designs now, which take me a little longer to assemble.

(I wind up with glue in places you would not believe!)

This was one of my earlier designs for a kitschy little brush stand. (Probably a bit of design overkill just to get it off the counter. Chuckle!)

This is the one that @Hirudin cut and assembled to help test parameterization last year…

(Link below if anyone wants to watch.)

I did wind up taking his suggestion and ran a 4mm dowel through the top part of the stand to give the upper fins a little more stability, and glued those into place. (Good call!)

Also got a chance to use the Engrave function in the GFUI to try to create a little pocket for the dowel. It takes multiple passes, but was definitely workable for a shallow mortise and tenon.

I’m tickled pink with how it turned out in the Maple and Walnut Proofgrade (1/8") ply. One thing that doesn’t get mentioned very often, but it makes a big difference in post-processing time, is that the Proofgrade has a slight satin finish already applied - you don’t really have to varnish it. It looks great without it and wipes off clean. (Making it great for kitchen pieces that might get splashed a bit.)

And it works! (My countertop is ever so much neater now.)

Update: Yeah, you want to go ahead and seal it. It lasted for about a year and a half but eventually the buildup of drips from the sponge caused the bottom to swell slightly. It still worked, but it looked a little strange so I pitched it.